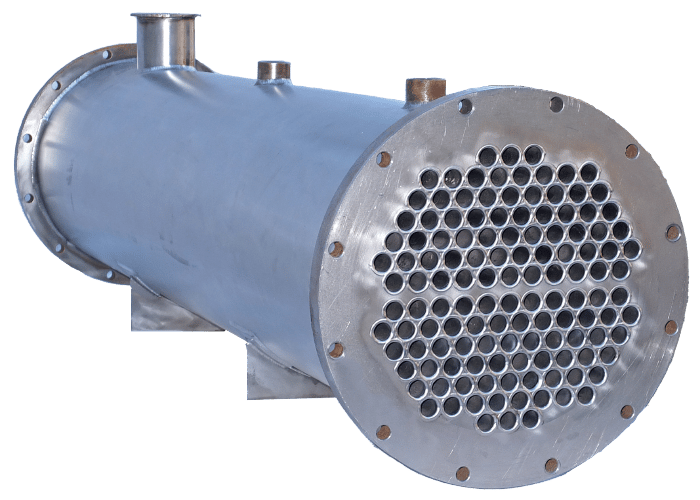

Titanium Marine Heat

Exchanger Manufacturer

For over 30 years, we’ve been using

Titanium in our marine heat exchangers.

It’s the ONLY material we use for sea water service.

Why Titanium?

Sea water contains chlorine (Cl), one of the most corrosive elements on earth.

Chlorine attacks galvanized and stainless steel, copper, brass and aluminum and these materials don’t do well in condenser / heat exchanger service.

Titanium is the solution to this problem because it is completely unaffected by the chlorine in sea water. Titanium is extremely tough and is will not fail if exposed to high water velocities in the tubes (+8 fps or more). NO zinc anodes are required, ever!

High sea water velocities create turbulence which provides a ‘self-scouring’ effect, keeping the tubes clean and free of marine growth and silt. Plugging is minimized and efficiency is maximized!

Request a Quote

We’d love to hear from you!

Please reach out to us so we can discuss your Titanium project.