Why Titanium Is Ideal For Marine Applications

Why Titanium Is Ideal For Marine Applications Historically, wooden ships didn’t rust, they rotted; steel ships don’t rot, they rust. There is still no free

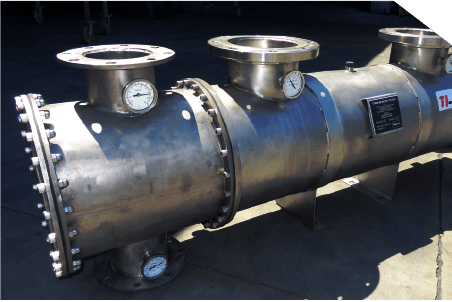

Titanium Marine Technologies designs and manufactures high–quality, titanium-based heat exchangers and wet exhaust elbows for a broad range of marine applications.

Markets include commercial boats, luxury yachts, military, fishing and passenger vessels around the world. Applications range from engine, machinery and exhaust cooling to air conditioning and refrigerated sea water systems. Call today or ask for quote!

For over 30 years, we’ve been using

Titanium in our marine heat exchangers.

It’s the ONLY material we use for sea water service.

Copper-Nickel, Brass, Carbon Steel, Stainless Steel and Aluminum all have weaknesses when it comes to sea water service. Only Titanium is completely resistant to attack by Chlorine, silt, high water flows and electrolysis.

Titanium may cost more per pound but less is required due to its superior mechanical properties, and it lasts for decades! Therefore, the “Total Cost of Ownership” is significantly lower than for lesser alloys and you never have to suffer unplanned downtime (resulting in lost revenue and reputation), collateral damage or environmental discharge (oil leaks).

We specialize in the production of titanium-crafted marine shell and tube heat exchangers and wet exhaust elbows.

Titanium is the solution to this problem because it is completely unaffected by the chlorine in sea water. Titanium is extremely tough and will not fail if exposed to high water velocities in the tubes (+8 fps or more) and corrosive sea water. NO zinc anodes are required, ever! This is why we offer a 10-year warranty on all of our products. For more details on why Titanium is ideal for Marine Heat Exchangers, click here!

Sea water is both corrosive and erosive, so copper and stainless-steel heat exchangers have a limited service life. Any heat exchanger that develops a leak can allow the machinery to become flooded with sea water with catastrophic results. Titanium is completely unaffected by sea water, lasting many years when properly maintained. Engines, A/C systems and hydraulic machinery are protected from collateral damage because the Titanium marine heat exchangers are so tough.

Wet exhaust systems are prone to corrosion due to acids in the hot exhaust streams when the components are made from stainless steel or copper. Titanium wet exhaust components last many times longer because they are unaffected by acid-based gases and the high 1,200 degree exhaust gas heat. Longer lasting Titanium exhaust systems cost less over the life of the vessel and prevent costly downtime.

Ten-year warranty on all products

Titanium Marine Technologies has changed the way that mariners think about heat exchangers. Using only Titanium for the sea water tubes and welding each tube in place, the reliability of a Titanium Marine condenser is incredibly high. Leaks at the tube face and corrosion in the tubes is no longer an issue because Titanium is completely impervious to salt water attack. No plastic or epoxy coatings are used in these heat exchangers so there will never be any failures due to tubesheet corrosion or erosion of the tube inlets. This allows us to offer the only 10-year warranty in the marine industry.

We’d love to hear from you!

Please reach out to us so we can discuss your heat exchanger or wet exhaust project.

Why Titanium Is Ideal For Marine Applications Historically, wooden ships didn’t rust, they rotted; steel ships don’t rot, they rust. There is still no free

Learn all you need to know about Titanium, Titanium heat exchangers, and more! Titanium Marine Technologies has vast knowledge of marine applications and services.