Wet Exhaust Elbows have to survive in the highly corrosive, 1,200F exhaust gases flowing out of the Turbocharger. With traditional Stainless Steel nozzles, you can expect only 2-3 years before the elbows develop leaks between the inner and outer shells.

When leaks occur and the engine is turned off, sea water can back-flow into the diesel engine, resulting in a catastrophic failure. A better material has to be available and Titanium is that material!

Each Wet Exhaust Elbow is made from 100% Aerospace titanium, the same material that is used in the construction of Jet Engines. The elbows come is sizes to fit most engines and special sizes can be made to order.

Wet Exhaust Elbows from Titanium Marine will never corrode in exhaust gas service, so the engine is protected from back-flooding and noxious exhaust gas leaks.

We understand the importance of protecting your time and money. This is why we focus on crafting only the highest quality exhaust elbows, using only Titanium. Contact us today to learn more about our water injected exhaust systems, sea water cooled exhaust, and water exhaust elbows.

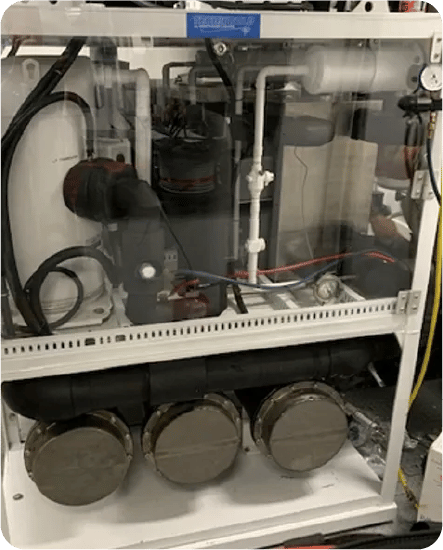

Your diesel main engines and generators need efficient cooling for long service life. Rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. Traditional copper-nickel engine coolers will fail over time and can pump raw sea water INTO the engines and auxiliaries.

This type of failure can cost tens of thousands of dollars and months out of service. With titanium jacket water and turbo intercoolers, you will have the most robust heat exchangers available. Your engines will run cooler and your valuable assets will be protected.