Why Titanium Is Ideal For Marine Applications

Why Titanium Is Ideal For Marine Applications Historically, wooden ships didn’t rust, they rotted; steel ships don’t rot, they rust. There is still no free

The 8,000 h.p. Lindsey Foss is one of the most powerful tugs working in the United States. The tug provides ‘Escort Support’ for the ultra-large crude tankers which bring oil down from the Alaskan slope. When the 20 year old gear box coolers began to fail, the Foss Company (owned by Saltchuk Resources) found that the original supplier of the heat exchangers could not supply replacements. The original units were from Germany and the OEM could not deliver replacements other than Cu-Ni. Additionally, US replacement options would require a lot of re-piping, hot work and shipyard time. The options were unsatisfactory for a company like Foss.

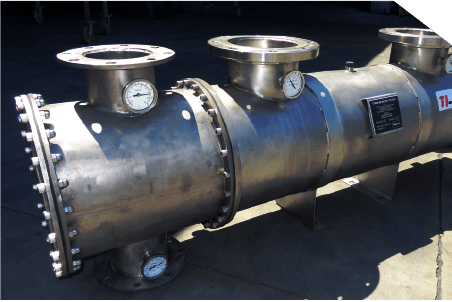

Foss contracted with Titanium Marine to supply new heat exchangers made with Titanium tubes. The caveat was that no hot work was allowed and the installation had to be fast. No blueprints were available so two ship surveys were conducted in Bellingham, Washington by Titanium Marine personnel traveling from Houston, TX. These ship checks provided the necessary dimensional information which in turn drove the construction of the four new oil coolers. All of this was done with a simple tape measure and a great deal of care. The coolers utilized the more expensive High Fin tubing (from Neotiss) for maximum thermal efficiency and a smaller package.

When the four new units arrived at the Foss Shipyard in Seattle, the installation went very smoothly. Two massive torque converters and the even larger Bull Gear & Pinion assemblies were outfitted with the new but same sized exchangers. No piping modifications were needed on the lubricating oil side, so all cleaning, passivating and pressure testing requirements were completely eliminated. In less than one week all four units were installed and the tug was ready to return to service.

Your diesel main engines and generators need efficient cooling for long service life. Rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. Traditional copper-nickel engine coolers will fail over time and can pump raw sea water INTO the engines and auxiliaries.

This type of failure can cost tens of thousands of dollars and months out of service. With titanium jacket water and turbo intercoolers, you will have the most robust heat exchangers available. Your engines will run cooler and your valuable assets will be protected.

Why Titanium Is Ideal For Marine Applications Historically, wooden ships didn’t rust, they rotted; steel ships don’t rot, they rust. There is still no free

Learn all you need to know about Titanium, Titanium heat exchangers, and more! Titanium Marine Technologies has vast knowledge of marine applications and services.