Titanium A/C Condensers

Luxury Superyacht Keeps in the Caribbean with

Titanium A/C Condensers

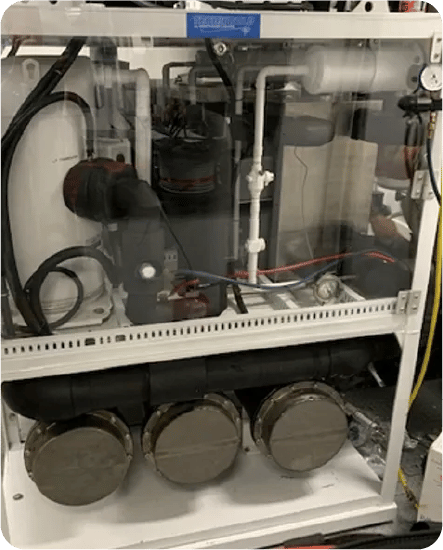

The M/Y Freedom is a luxury superyacht domiciled in Fort Lauderdale, Florida. On two prior occasions the A/C condensers had breached (salt water had leaked into the refrigeration circuits) and the repairs were long and costly. After the repeated failures of the A/C condensers the vessel management elected to install Titanium Marine condensers. Looking for more reliability, the vessel management decided to move away from Copper based exchangers and go with robust Titanium tubes.

The replacement units were made using super-efficient “High Fin” tubing for extra performance and this allowed for smaller diameter condensers. The challenge was making the new exchangers fit into the very tight spaces of the original units. The units were fabricated to precisely mimic the piping connection points so that they could be bolted right up with a minimum of man-days, simple hand tools and no hot work.

RSW & FREEZING SYSTEMS

Your diesel main engines and generators need efficient cooling for long service life. Rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. Traditional copper-nickel engine coolers will fail over time and can pump raw sea water INTO the engines and auxiliaries.

This type of failure can cost tens of thousands of dollars and months out of service. With titanium jacket water and turbo intercoolers, you will have the most robust heat exchangers available. Your engines will run cooler and your valuable assets will be protected.

- Smaller, lighter, with longer service life

- Reduce engine jacket water temperatures

- Cooler running for propulsion gearboxes and HPUs

- Eliminates zinc anode maintenance

- All tubes 100% seal welded