For over 30 years, we’ve been using

Titanium in our marine heat exchangers.

It’s the ONLY material we use for sea water service.

Titanium Heat Exchanger Projects

Successful Projects

In 2020, the M/Y Ocean Club experienced failure of one of it’s Copper-Nickel A/C condensers; less than two months after putting the unit into service. The Copper unit just did not last!

The Captain knew that there had to be a better solution than just “Rip and Replace, and he went looking for a Titanium alternative. He knew from experience that Titanium was impervious to the effects of sea water.

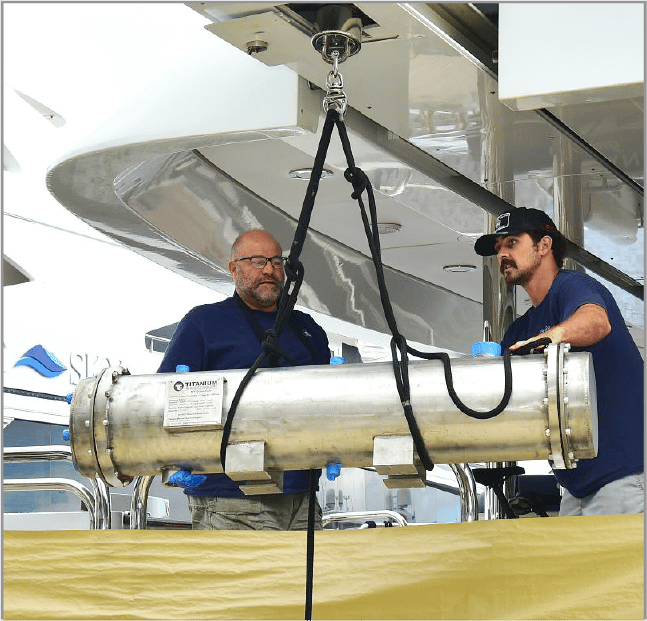

Titanium Marine Technologies was able to supply a Titanium A/C condenser that had the same dimensions and connection geometry, allowing for a quick installation. This heat exchanger literally “dropped right in” to the available space.

The following season the second condenser failed (at sea) and another Titanium Marine condenser was put on order and installed. The M/Y Ocean Club has had no more A/C issues and all is “Cool” onboard!

Capt. Herb MagneyM/Y Ocean Club

RSW & FREEZING SYSTEMS

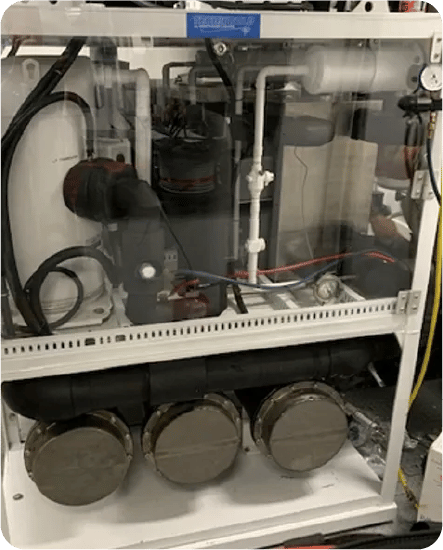

Your diesel main engines and generators need efficient cooling for long service life. Rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. Traditional copper-nickel engine coolers will fail over time and can pump raw sea water INTO the engines and auxiliaries.

This type of failure can cost tens of thousands of dollars and months out of service. With titanium jacket water and turbo intercoolers, you will have the most robust heat exchangers available. Your engines will run cooler and your valuable assets will be protected.

- Smaller, lighter, with longer service life

- Reduce engine jacket water temperatures

- Cooler running for propulsion gearboxes and HPUs

- Eliminates zinc anode maintenance

- All tubes 100% seal welded