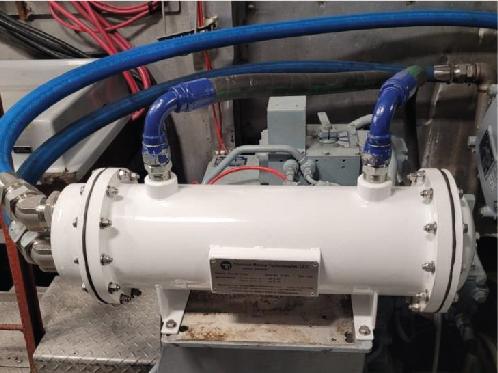

HPU Oil & Marine Gear Box Coolers

Protecting the valuable propulsion gear boxes is critical to maintaining normal operations. The heavy gear oils must be kept at the optimum temperature in order to provide proper viscosity / lubricity on the gear sets. Controlling gear oil temperature can be a moving target as water temps change in transit.

Recently, sophisticated “high tech” gear box coolers have been showing up in smaller vessels with a lot of downstream trouble resulting. These HPU oil coolers have very small diameter, bi-metal tubes with a huge number of thin fins pressed around the tubes, inside the shell. We are finding that these assemblies can leak oil past the tube stack rubber seals and into the overboard discharge streams. Because of this, our gear-box coolers set the quality standard of the production of HPU oil systems.

This leaking oil then travels over the side and onto the water where regulators can penalize the vessel operator. For this reason, NO rubber seals are used in Titanium Marine heat exchangers. Titanium Marine uses large diameter tubes to allow for the passage of sea grass, shells and debris. And, because Titanium is physically tough, high tube velocities provide a ‘self scouring and cleaning’ which keeps the tubes working efficiently.

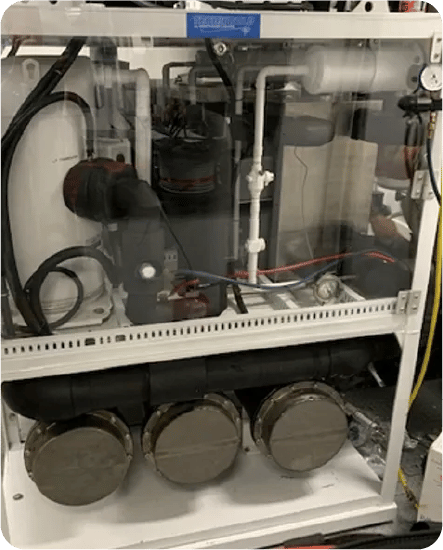

RSW & FREEZING SYSTEMS

Your diesel main engines and generators need efficient cooling for long service life. Rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. Traditional copper-nickel engine coolers will fail over time and can pump raw sea water INTO the engines and auxiliaries.

This type of failure can cost tens of thousands of dollars and months out of service. With titanium jacket water and turbo intercoolers, you will have the most robust heat exchangers available. Your engines will run cooler and your valuable assets will be protected.

- Smaller, lighter, with longer service life

- Reduce engine jacket water temperatures

- Cooler running for propulsion gearboxes and HPUs

- Eliminates zinc anode maintenance

- All tubes 100% seal welded