Marine Jacket Water Cooler & Diesel Engine Cooling

Engines create a lot of heat, with over 60% of the energy going up the stack or over the side. The most effective way to keep the engine jacket water cool is to reject the heat to the ocean.

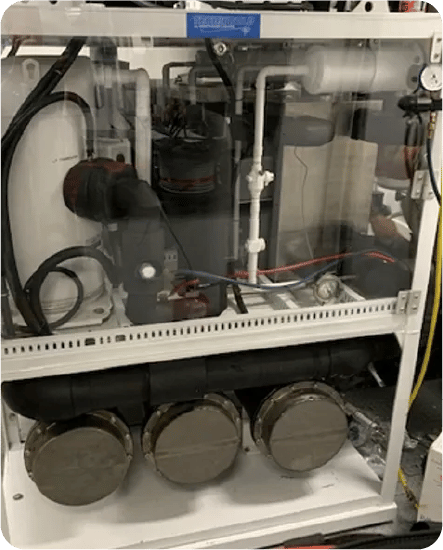

Shell & Tube heat exchangers can handle these high loads, preventing engine damage due to overheating. Using Titanium tubes, tubesheets and headers, the Jacket Water coolers will never “cross contaminate” the treated water in the engine. An occasional in-situ cleaning is all that is required to maintain top performance. A cool running engine will see an extended service life along with decreased maintenance costs.

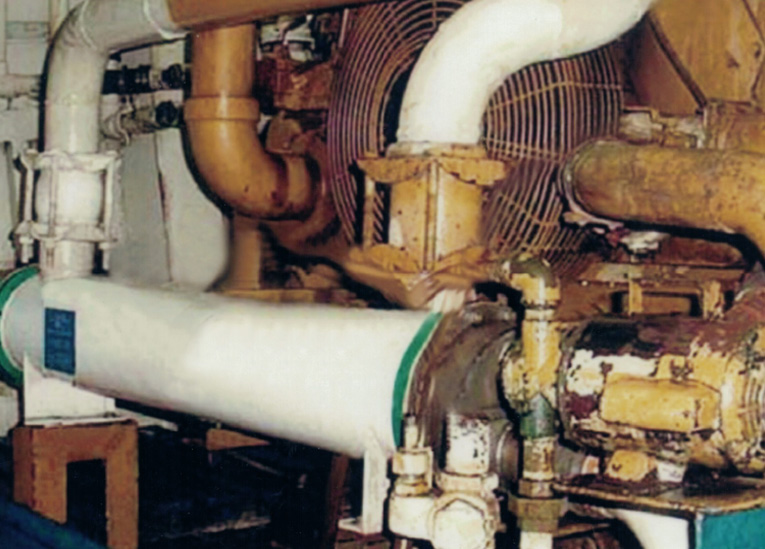

Installing and mounting a light weight Titanium Jacket Water Cooler is highly flexible. The units can be placed on or near the engine, on the bulkhead or even in the bilge. Simple hose or piping connections make the installation fast and cost effective.

Titanium Marine specializes in the production of jacket water coolers & diesel engine cooling systems.

RSW & FREEZING SYSTEMS

Your diesel main engines and generators need efficient cooling for long service life. Rejecting engine heat to the ocean requires thousands of gallons per hour of sea water flowing through the jacket water and turbo intercoolers. Traditional copper-nickel engine coolers will fail over time and can pump raw sea water INTO the engines and auxiliaries.

This type of failure can cost tens of thousands of dollars and months out of service. With titanium jacket water and turbo intercoolers, you will have the most robust heat exchangers available. Your engines will run cooler and your valuable assets will be protected.

- Smaller, lighter, with longer service life

- Reduce engine jacket water temperatures

- Cooler running for propulsion gearboxes and HPUs

- Eliminates zinc anode maintenance

- All tubes 100% seal welded